The Evolution of In-Mold Decorations in Production Processes

The Evolution of In-Mold Decorations in Production Processes

Blog Article

Grasping In-Mold Decorations: Strategies, Patterns, and Best Practices for Ideal Outcomes

In the world of production, the art of in-mold designs stands as a crucial aspect of product layout and production. In-Mold Decorations. By delving into the methods, trends, and best practices that underpin successful in-mold decoration processes, businesses can unlock a world of possibilities that not only elevate the aesthetic allure of their products however additionally simplify manufacturing performance and strengthen customer interaction.

Material Choice

Material selection is a critical aspect of grasping in-mold designs, as it directly impacts the high quality and resilience of the final product. When choosing materials for in-mold decors, it is vital to think about factors such as compatibility with the molding procedure, the wanted aesthetic end result, and the environmental conditions the item will deal with. Polycarbonate materials like polycarbonate, ABS, and polypropylene are frequently utilized for in-mold decorations as a result of their flexibility and ability to achieve elaborate designs. These products offer superb moldability, enabling makers to create complex shapes and patterns with accuracy.

Furthermore, the picked product ought to possess great attachment properties to make certain that the design sticks firmly to the substratum throughout the molding procedure. Attachment in between the product and the decor is crucial for stopping delamination and making certain durable visual allure. Furthermore, materials with high heat resistance are favored for in-mold designs, specifically for items that will certainly be subjected to elevated temperature levels throughout their lifecycle. By meticulously choosing the ideal material for in-mold decorations, manufacturers can enhance the overall top quality and sturdiness of their products, fulfilling the assumptions of both clients and end-users.

Design Technology

A vital aspect in advancing the field of in-mold designs is the constant expedition and application of layout innovation strategies. Style innovation plays a crucial function in enhancing the aesthetic allure, capability, and total top quality of items manufactured using in-mold design procedures. By incorporating ingenious style aspects, producers can differentiate their items on the market, draw in consumers, and remain in advance of competitors.

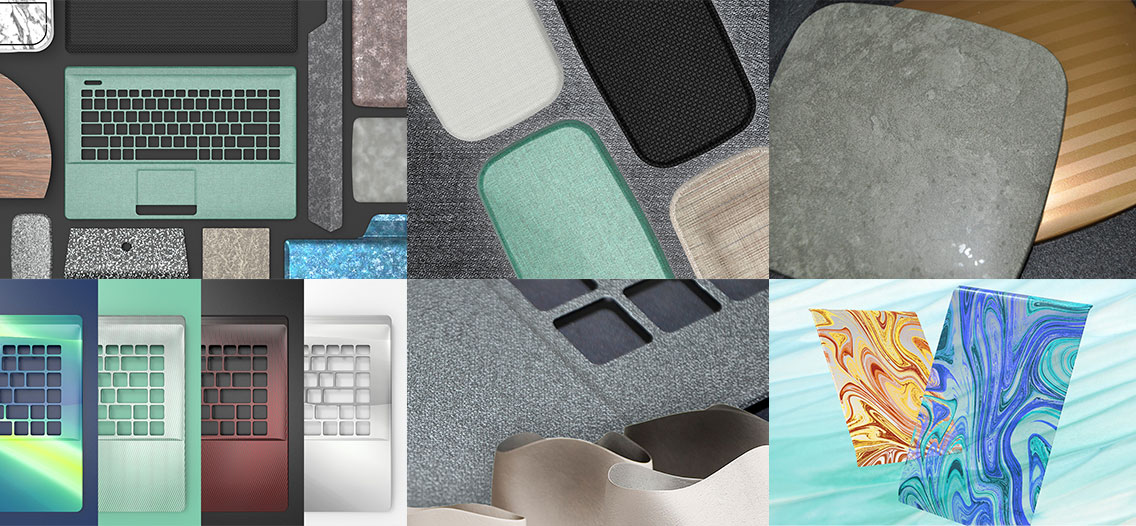

Among the key aspects of style innovation in in-mold decors is the integration of elaborate patterns, textures, and graphics that were previously testing to achieve with traditional design methods. Advanced innovations such as 3D printing and digital layout devices enable developers to create complicated and detailed layouts that can be effortlessly moved onto molded components. Furthermore, using dynamic shades, metallic coatings, and special impacts like gloss or matte appearances can even more boost the visual charm of in-mold decorated products.

In addition, design advancement extends beyond looks to encompass practical improvements such as ergonomic forms, integrated functions, and personalized elements that cater to details customer demands. By welcoming design advancement, manufacturers can unlock new opportunities for creative thinking, personalization, and product differentiation in the competitive landscape of in-mold designs.

Production Effectiveness

Effective production procedures are crucial for converting the ingenious designs created in the area of in-mold designs into high-grade completed products that meet market needs and customer expectations. In the world of in-mold designs, production performance includes various vital elements that contribute to the total success of the manufacturing procedure.

Furthermore, executing automation and robotics in the assembly line can dramatically enhance efficiency by simplifying repeated tasks and minimizing the margin of error. Automation not just accelerates the manufacturing process but likewise enhances accuracy and repeatability, causing a much more high-grade and uniform final product. Taking on lean manufacturing principles, such as just-in-time supply monitoring and waste reduction methods, can better enhance production performance by minimizing downtime and enhancing source utilization. In general, an alternative strategy to manufacturing efficiency is vital in taking full advantage of the possibility of in-mold decor techniques and achieving ideal lead to the open market landscape.

High Quality Control Actions

What are the vital methods for making certain rigorous top quality control procedures in the realm of in-mold designs? Quality control measures are extremely important in in-mold decoration procedures to make sure the manufacturing of flawless and high-quality completed items.

Using innovative innovations such as computerized evaluation systems can additionally enhance the high quality control procedure by offering trusted and accurate data for evaluation. These systems can spot flaws that might be missed by manual assessments, thereby improving general item top quality and consistency.

Normal training and development programs for employees associated with the in-mold decor procedure can also contribute to preserving high-grade standards. By educating personnel on finest techniques, top quality expectations, and the importance of interest to detail, business can cultivate a society of top quality consciousness throughout the organization.

Consumer Appeal

To boost the bankability of in-mold decoration items, providing and understanding to customer preferences play a crucial role in establishing their charm and success. Offering modification options such as tailored styles, shade variations, and textural components can considerably boost the allure of in-mold decoration items.

Conclusion

In-mold decorations offer a effective and flexible way to enhance item appearances. Understanding in-mold decors calls for a holistic approach that takes into consideration all elements of the manufacturing procedure to make sure success.

In the realm of production, the art of in-mold decors stands as an essential aspect of item style and production. Layout advancement plays an essential role in boosting the aesthetic allure, performance, and overall top quality of products made using in-mold decor processes.One of the vital elements of layout advancement in in-mold decorations is the assimilation of elaborate patterns, appearances, and graphics that were previously testing to achieve with standard decoration techniques.Efficient production procedures are go to this web-site vital for converting the ingenious layouts developed in the area of in-mold decors into high-quality finished products that satisfy market needs and consumer assumptions. Supplying customization choices such as individualized layouts, color variants, and textural elements can substantially enhance the charm of in-mold decor items.

Report this page